Apple’s new AirTag item trackers are pretty small, but not quite small enough to slip into most wallets without adding an obvious bit of bulk.

Fortunately, as one talented AirTag owner has found, that’s nothing you can’t fix with a heat gun, a bit of soldering and an understanding that you could totally fry your shiny new AirTag in the blink of an eye. Oh, and a 3D printer.

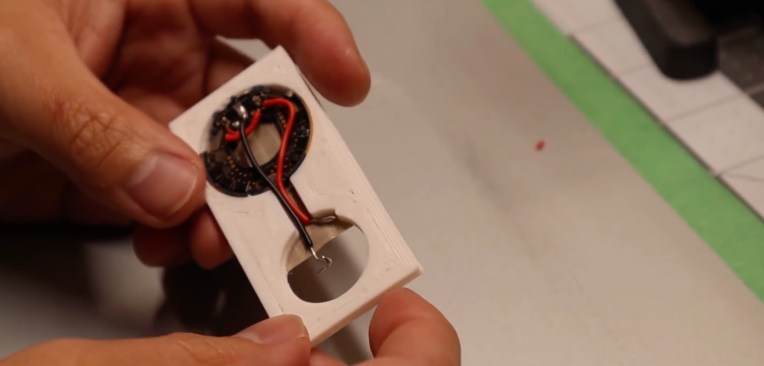

When Andrew Ngai realized that much of AirTag’s thickness came from its PCB and its battery being stacked atop each other, he set out to instead arrange them side-by-side. With the help of some iFixit guides (which, by the way, provide an awesome peek inside the AirTag if you’re curious what’s in there but aren’t looking to dissect one yourself), Andrew tore the AirTag down to its key components. After making sure everything still worked in its freshly disassembled state, he 3D printed a new case, soldered in wires to connect the board to the battery at a distance, and put everything back together. Success! And he did it all within just days of AirTag being released.

While this sort of project requires a pretty broad set of skills to pull off, Andrew has kindly handled one of the steps for anyone looking to take it on: he’s uploaded the STL file for the 3D-printed card holder as a free download on Thingiverse. (Or you could, of course, just buy a Tile Slim. But that doesn’t involve soldering irons and 3D printing, so where’s the fun in that?)

[via 9to5mac]

Recent Comments